DCL Series DC Reactor

Summary

Reduce the current ripple in DC circuit, ensuring continuous current when inductance value reach to a certain degree. Reduce and prevent the rectifier bridge damage and capacitance overheating caused by pulse current. Improve power factor, reduce the AC pulse to the DC busbar. Limit grid voltage transient.

Normal working conditions

1. Altitude for installing place should not exceed 1000m.

2. Ambient temperature -25ºC~+45ºC, Relative humidity is not exceed 90%.

3. Environment exists without harmful gas, steam, chemical deposition.

4. The surrounding environment should be good ventilation conditions, such as in the cabinet, should be equipped with ventilation equipment.

Technical Performance Parameters

1. Rated operating voltage: 400V-1200V/50Hz

2. Rated operating current: 3A to 1500A @ 40 ℃

3. Electric strength: iron core-winding 3000VAC/50Hz/10mA/60s no arcing no breakdown;

4. Insulation resistance: iron core-winding 1000VDC, Insulation resistance ≥100MV

5. Noise of reactor: less than 35dB (measured from 1 meter away in horizon from reactor)

6. Degree of protection: IP00

8. Degree of Insulation: F above

9. Applicable standard: IEC289: 1987 "Reactors"

GB10229-88(eqv IEC289:1987)

GB10229-88"Reactors"(eqv IEC289:1987)

JB9644-1999"Reactor for semi-conductive electric driving use"

Application

Improve the input current wave resulted by capacitor harmonics

Reduce and prevent the rectification bridge being damaged and capacitor being overheating due to surging current. Improve power factor, reduce DC busbar AC pulse.

Restrict the transient change of system voltage

Model & Its meaning

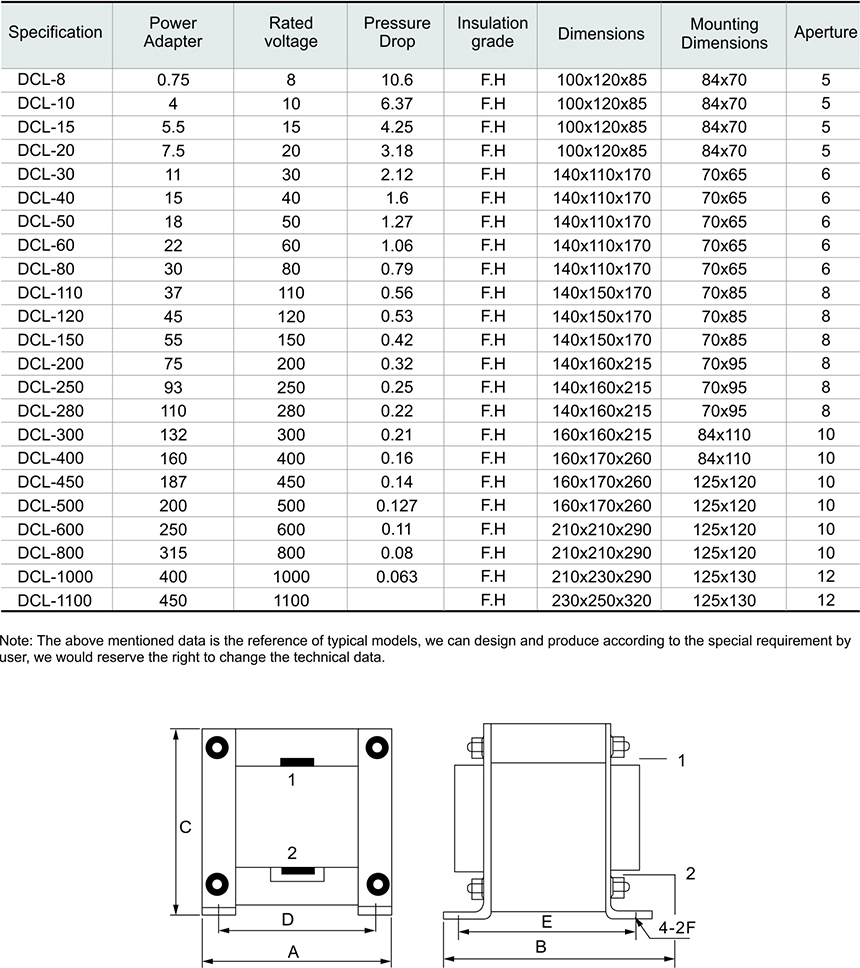

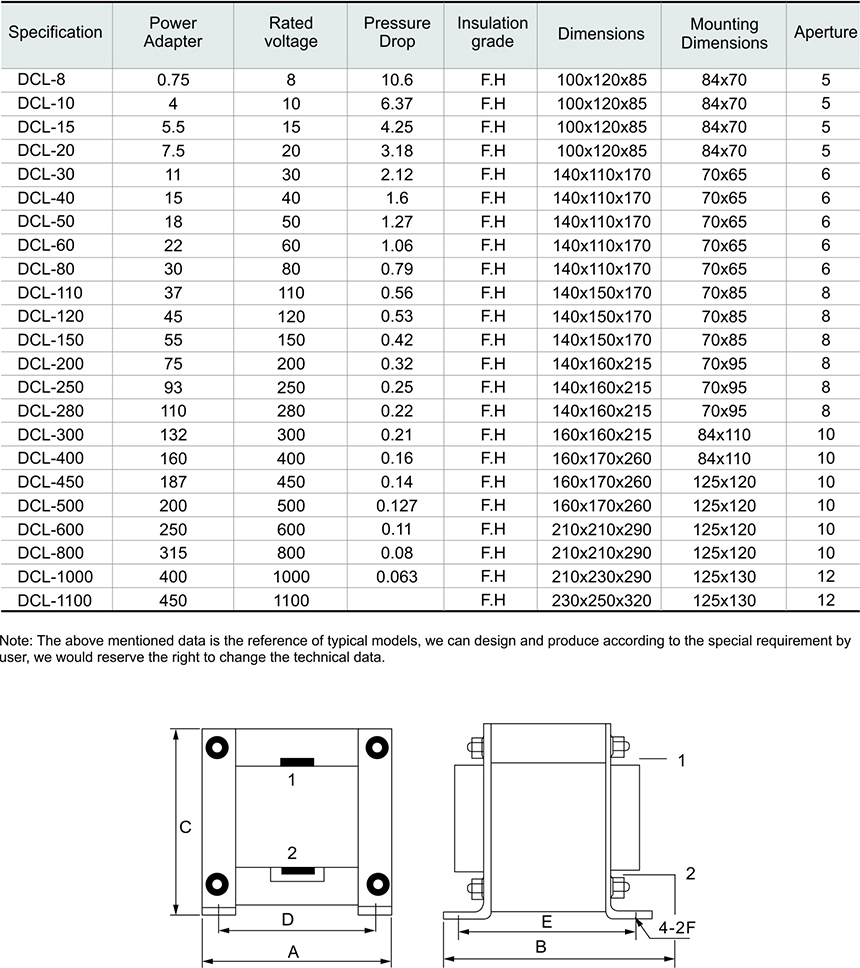

Product Specifications & Parameters

Product Specifications & Parameters

Note: The above specifications are common specifications for reference only. Reactors of other voltage levels, different capacities and different voltage drop rate can be manufactured according to user's requirements.